Ultra Fine Bubble Shower Head

1.Overview of Ultra Fine Bubble (UFB) Showerheads

◾ What is Ultra Fine Bubble (UFB)?

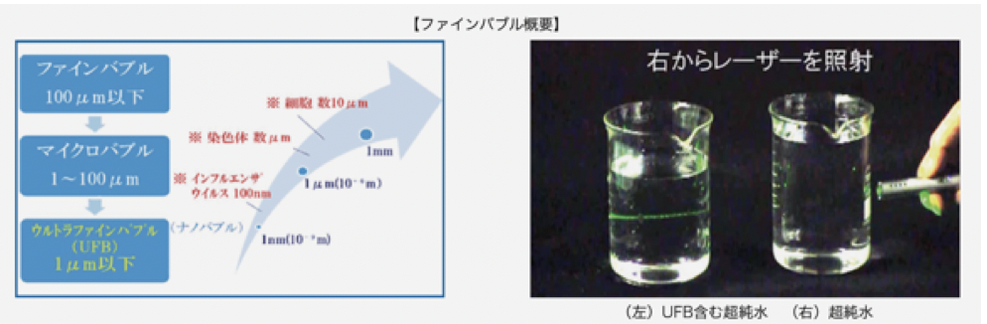

- Fine bubbles are smaller than the bubbles we see in our daily lives. Specifically, bubbles smaller than 0.1 mm (100 μm) in diameter are called fine bubbles.

- Microbubbles are 1 to 100 µm in diameter and ultrafine bubbles (UFB) are 1 µm or less in diameter.

- Microbubbles are visible to the naked eye as cloudy white water, while ultrafine bubbles are invisible to the naked eye.

- If the distance from the batter's box to the outfield fence on a baseball field is 1 mm, the size of a grain of sand on a baseball field is equivalent to the size of an Ultra Fine Bubble. (Partially exhibited from AIST) If the distance from the batter's box to the outfield fence on a baseball field is 1 mm, the size of a grain of sand on a baseball field is equivalent to the size of an Ultra Fine Bubble. (Partially exhibited from AIST)

◾ Overview of Ultra Fine Bubble Technology

- Ultrafine bubble is an innovative technology originating in Japan, and is expected to become the basis for the development of our country's key industries in the future.

- Ultrafine bubble technology is generated by mixing gas and liquid, and is being used in various fields such as cleaning, sterilization, water purification, and handling of objects in liquids in the fields of mining, agriculture, forestry, fisheries, and infrastructure.

◾ About Ultra Fine Bubble Generator

- The Ultra Fine Bubble (UFB) generator is a device developed to cool and clean the blades of industrial cutting machines by circulating water.

- One of the main features of the UFB generator is that it has a mechanical dirt removal and cleaning effect. This product was developed for the purpose of stable mold cooling by removing dirt from the cooling tank and chiller tubes, preventing water corrosion, and improving and eliminating clogs in the tubes by cleaning them. In addition, since the water is purified, it can be expected to improve the environment, save water by reducing the frequency of water replacement (refilling), and reduce labor costs by shortening the cleaning time.

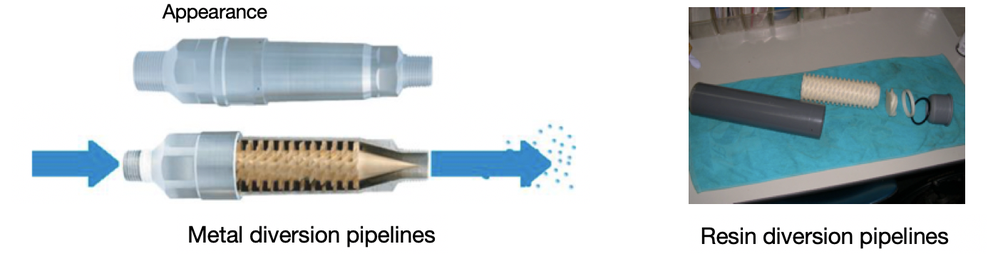

- When liquids are intensely agitated and mixed, turbulence is generated and a "coanda effect" (i.e., clinging and sticking) is observed. Furthermore, when these liquids are agitated and mixed, "ultra-fine bubbles" are generated.

- In order to more effectively draw out the performance of the processing fluid as described above, the equipment applies "flip-flop flow. Flip-flop flow" refers to the phenomenon in which a fluid such as water is passed through a square tube with diamond-shaped columns arranged in a mesh-like pattern, and the vortex created in the tube causes the liquid jetting out from the tube body to switch from side to side in a regular manner.

- The complex internal structure of the device is the crystallization of technology backed by the latest fluid theory. (The complex internal structure of the device is the crystallization of technology backed by the latest fluid theory.)

- This UFB water generator is effective when the water pressure is 1Kgf or higher. Since ordinary tap water has a water pressure of 2 to 4 Kgf, it works with tap water.

We have succeeded in generating UFB with a single component rather than a large piece of equipment, and have adapted this principle to a shower head for home use, which is the UFB shower head introduced here.

- Many UFB generators from other companies use water, air, and pressure pumps to generate UFB. The equipment itself is very large, costly, and requires a lot of space.

- Our UFB generator is very compact and can be installed in a small space because it generates UFB by twisting oxygen in water using only water pressure.

- The main features of our equipment are that it does not require power and that the size can be selected according to the application.

- Since no activated charcoal, tourmaline stones, etc. are used, there is no need to replace the contents, and the product can be used semi-permanently as long as the main unit is not broken.

- The bubbles generated by the UFB showerheads are very large in nano-sized bubbles, so the benefits of UFBs can be experienced in a remarkable way.

※ According to data measured by the Nano Site System of Quantum Design Japan, an external research organization, 60 to 70 million bubbles per 1 cc of UFB were observed.

2.Ultra Fine Bubble (UFB) Shower Head Features

It provides sufficient cleaning effect without the use of solvents such as shampoo, soap, or body soap. Ultra Fine Bubbles penetrate even the smallest of pores, adsorbing dirt and leaving it clean, and their high cleaning power has been proven, making them safe for use by anyone, including those with sensitive skin or those who are concerned about sebum or dirt! The product is safe for use by all.

② Odorless and clean

Even if you wash your hair without solvent, you will find that the hair is very fluffy and odorless after washing. The cleansing and washing effects can be experienced and maintained, as well as preventing diseases caused by dirt adhering to the skin.

③ Time reduction

As mentioned above, no solvents are required, resulting in shorter cleaning times, which leads to shorter bathing times.

④ Equipment set up fortifications do not

The shower head can be easily replaced with a shower head in an ordinary home bathroom, eliminating the need for installation work.

⑤ Economic effect

Since it does not use activated charcoal or tourmaline stones, there is no need to replace the contents, and it can be used semi-permanently as long as the main unit is not broken. Our UFB showerheads can be purchased for less than 30,000 yen, so the hurdle to purchase is low.

In addition, by showering on the mirror every day when taking a bath, you can see how the hot water stains are removed day by day and the mirror becomes shinier and shinier.

Also, the removal of dirt and grime, as well as the cleaning effect, can be confirmed to improve or eliminate plumbing problems.

◾ Improvement of stains after installation in plumbing for toilet flushing

※ Four months after installation in the plumbing for toilet flushing, the yellowing and blackening of the toilet bowl was removed and improved.

3. Example of Ultra Fine Bubble (UFB) Generator

West Nippon Expressway Company Limited (NEXCO West Japan)

◾ Efforts to Advance Highway Maintenance Management Using Ultra Fine Bubbles

West Nippon Expressway Co., Ltd. is utilizing new technologies to enhance expressway maintenance and management and to improve service quality (CS).

◾ Ultra Fine Bubble Water for Toilet Cleaning Initiatives

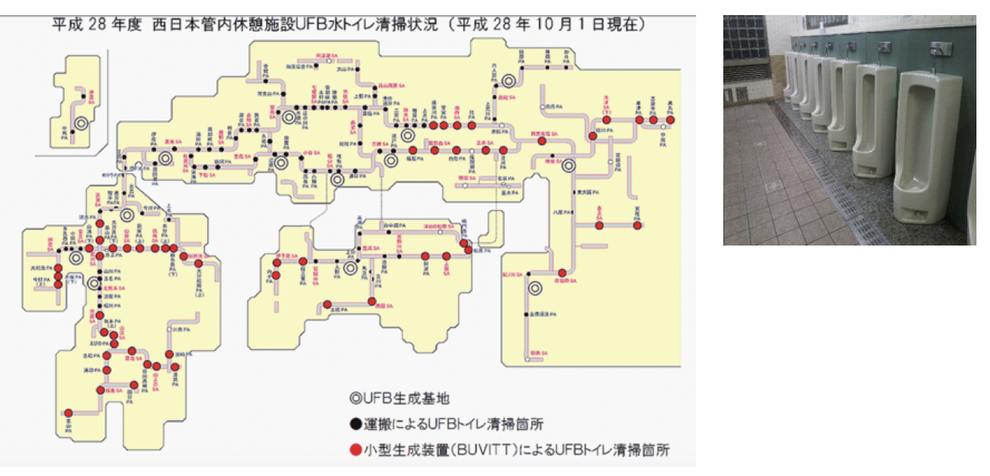

We view restrooms at rest facilities as an important point of contact with users, and since privatization, we have been focusing on drastic improvement of the restroom environment. As part of these efforts, a new restroom cleaning method using ultra fine bubble water ("UFB water") was launched at rest facilities in the Chugoku region in FY2010, and is being gradually expanded to rest facilities throughout western Japan.

Effect

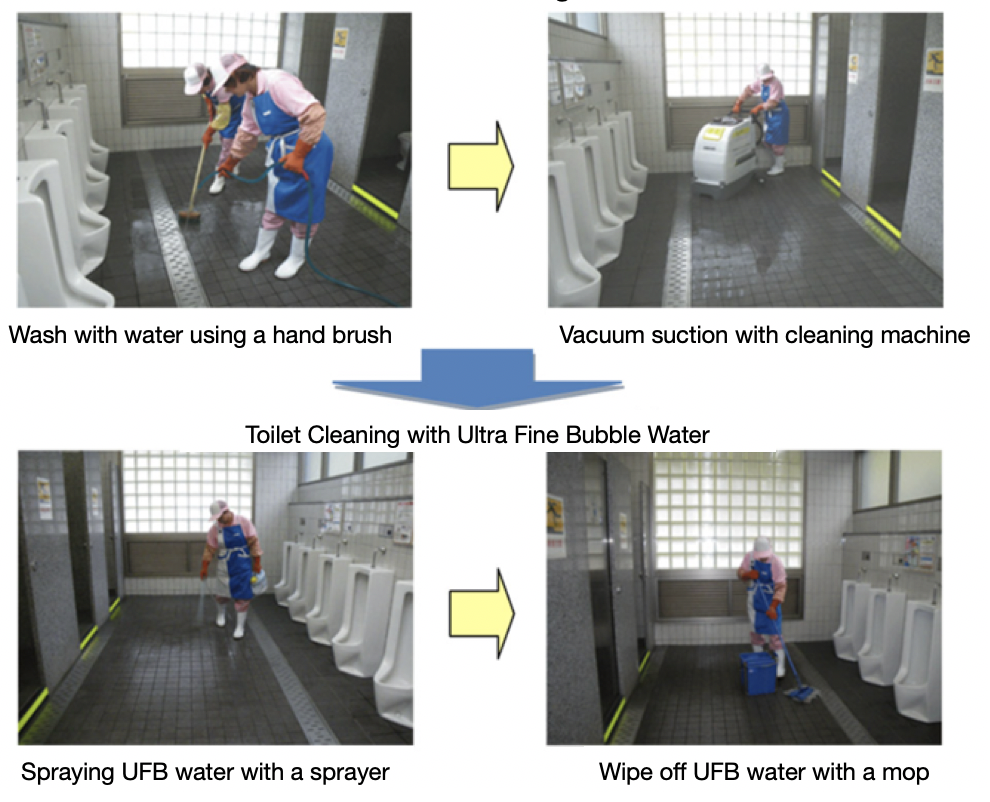

This cleaning method consists of spraying UFB water on the toilet floor with a sprayer and wiping it off with a mop, with the following effects.

Effect ① Significant reduction in overall work time

Compared to conventional washing in water with detergent, the work time is reduced by 30% with light equipment.

Effect ② Significant reduction in water consumption

The amount of water used is significantly reduced, and the amount of detergent used is small, thus reducing the environmental impact to 1/100th of the previous level.

Effect ③ Reduced floor drying time

Floor drying time is reduced by 40%, and customers' feet do not slip.

◾ West Nippon Expressway Company Limited (NEXCO West Japan)

- In the beginning, UFB generators (BUVITAS) were placed at transportation bases and transported to each rest facility by truck, etc. In 2014, Ligaric Co., Ltd. successfully developed a compact UFB generator (BUVITT), and we are now working to install it at all rest facilities in our jurisdiction under a five-year plan starting in 2015.

- Based on the above, the UFB cleaning implementation rate for application to rest facilities is now approximately 90% within NEXCO West's service area.

Conventional cleaning methods

◾ Bridge Girder Cleaning Initiatives

(1)Objective

Efficient maintenance, repair, and renewal of structures is an important issue for extending the service life

of structures, and it is imperative to do so efficiently within a limited budget. In particular, the aging of

bridges is a problem not only because of damage to bridges caused by larger vehicles and overloading,

but also because of accelerated deterioration due to the adhesion of salt to bridge girders from bridge

joints caused by flying salt on routes passing near the coast and the application of anti-freeze (sodium

chloride) to secure road surfaces during the winter. This has become a problem. Therefore, from the

viewpoint of preventive maintenance, salt is removed by washing bridge girders.

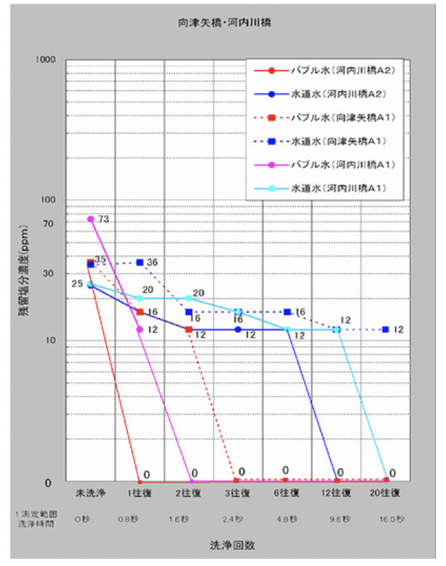

(2)Ultra Fine Bubble Water Cleaning

In bridge girder washing, it has been confirmed that UFB water can remove salt relatively quickly

compared to ordinary water, improving work efficiency. For this reason, we have begun using UFB water

for bridge girder cleaning.

【 Residual salinity diagram 】

◾ Initiatives to Reduce Sludge Volume at Rest Facilities

(1) Purpose of Technology Development

Approximately 40% of the 303 rest facilities in NEXCO West Japan's service area use septic tanks for

treatment. The cost of sludge disposal is increasing every year, and reducing this cost is an urgent issue,

along with reducing road maintenance costs, which will increase in the future. In order to solve this problem, we have been conducting research and development on the application of ozone gas (O3) ultrafine bubble (O3UFB) technology to septic tanks in collaboration with Hiroshima University (Prof. Nishijima) since FY 2013.

(2) Sludge Volume Reduction Mechanism

A. Shear and refine sludge floc

Excess sludge is sucked into the UFB generator and shear stress is applied to the sludge floc together with gas, causing it to become finer.

B. O3UFB penetrates inside the miniaturized sludge floc

The ultrafine bubbles of O3UFB easily penetrate into the sludge floc and accelerate the reaction inside the floc.

◾ Research Status

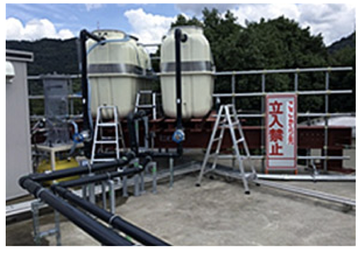

- Currently, an experimental plant has been installed at the Okuya parking area (PA) on the Sanyo Expressway to establish a sludge volume reduction technology using O3UFB.

- As of August 2016, the volume reduction rate of 70% was achieved, and the tanks were removed by the end of the fiscal year. Based on the results of this study, we are considering applying the results to septic tanks in rest facilities that will be newly built or reconstructed in the future.

【 Okuya PA Demonstration Experiment Status 】

UFB Shower Head Introduction Movie

合同会社レジェルマン

〒160-0023

東京都新宿区西新宿1-20-3

西新宿高木ビル 8F

TEL:03-6890-3460

FAX:03-6890-3341

info@legerement.net